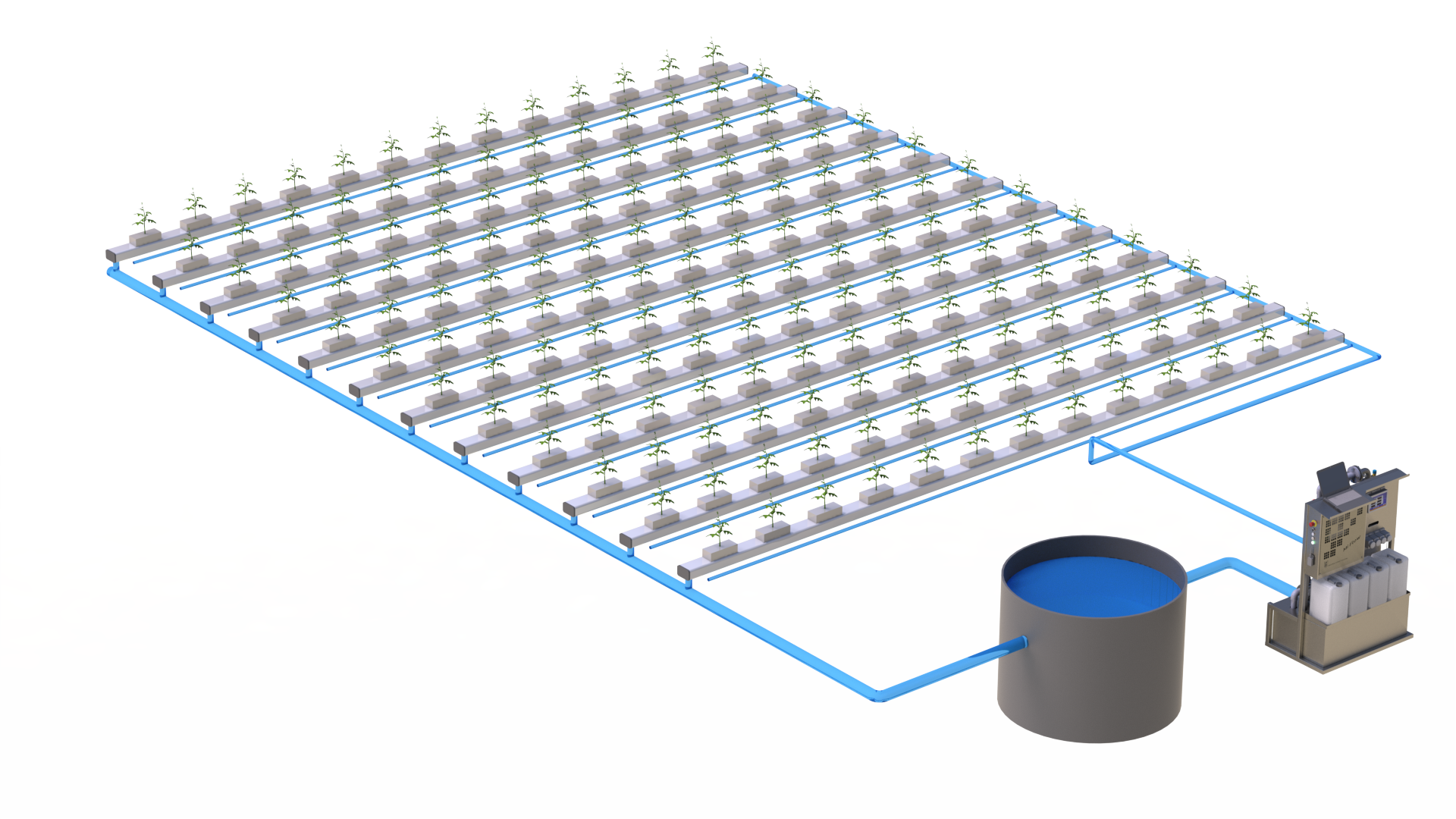

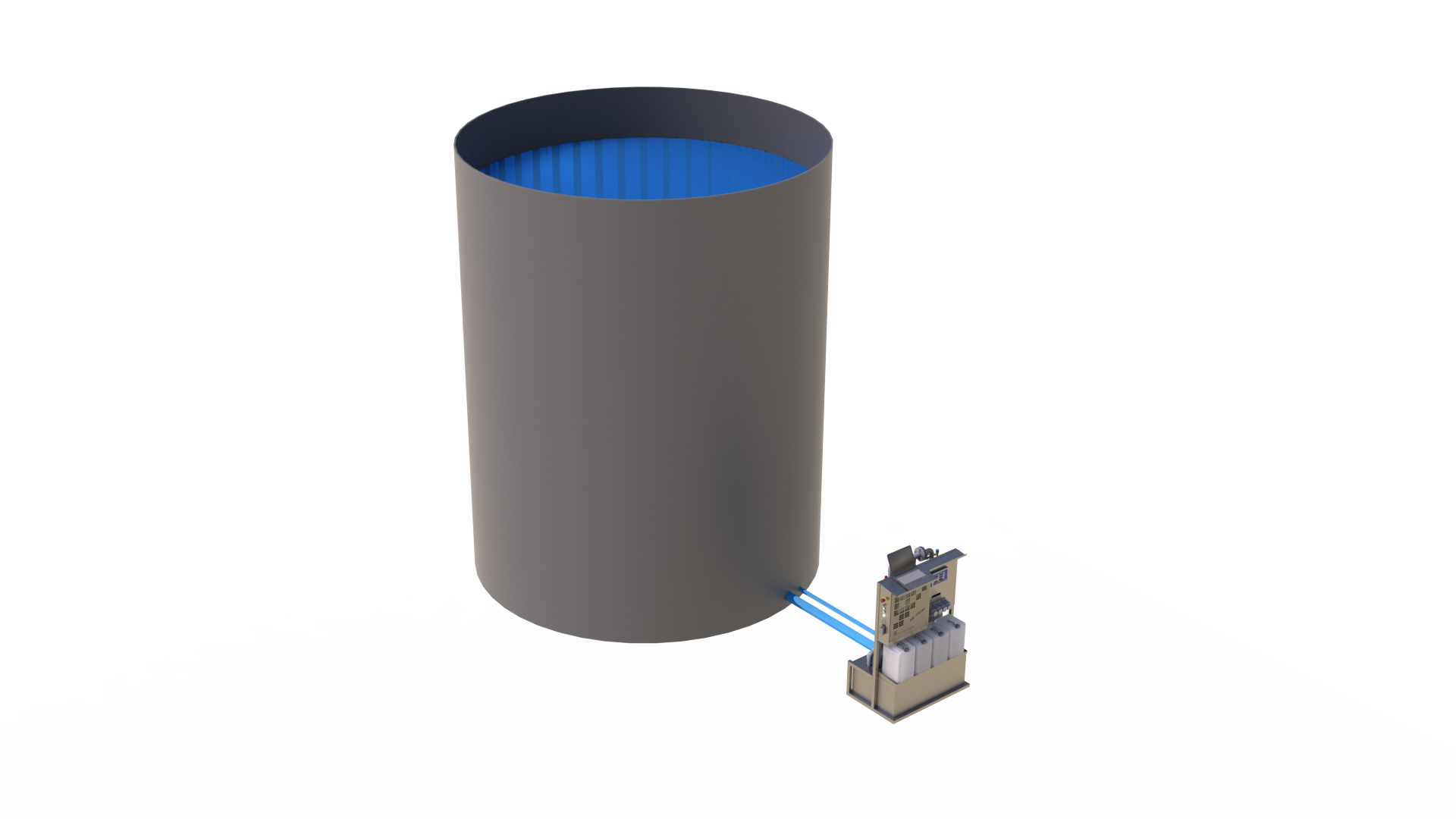

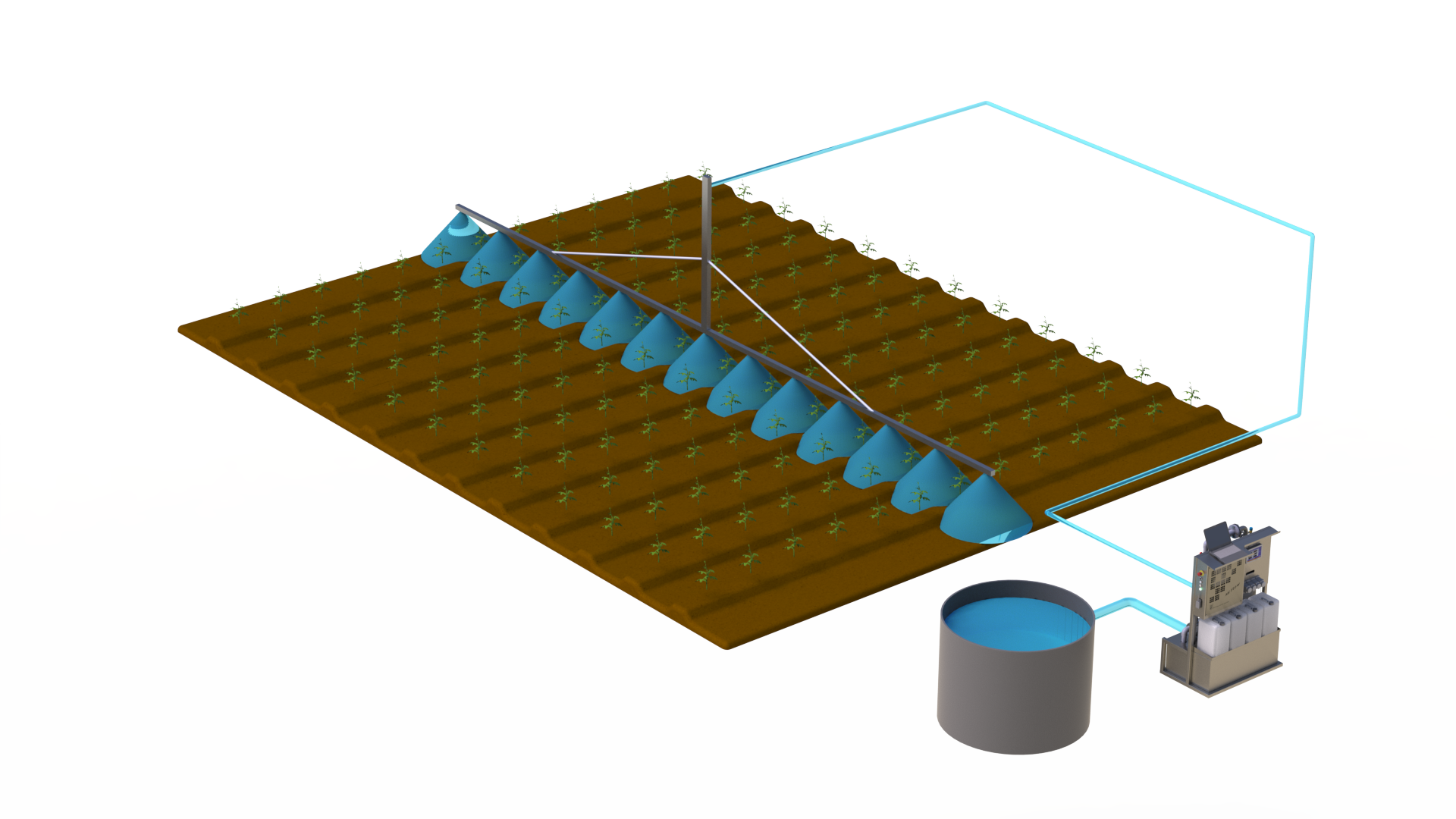

Mi Flow is a high-quality solution for smaller capacities that is not inferior to the results of larger water units. Thanks to the smart and simple configuration, you get a lot of professionalism at a low cost. Whether you are looking for a water unit for your DFT/NFT systems, want a higher level of automation when making your feedwater, drip system, irrigation or want to start a small new crop? The Mi Flow water unit is off all trades.

The control of the Mi Flow water unit is fully automated up to and including an online control. This makes the Mi Flow a turn-key solution that is easy to install yourself (Plug & Play).

The mixing is done by means of a pre-mix system in a mixing tank.

Technical specifications base:

• 1 x Automatic float for filling cleanwater

• 1 x Return water connection

• 1 x Press line connection 1.5 – 2bar

• 1 x manual filter 100mu in press pipe.

• 1 x Control unit Bluelab with measurement of EC, PH, T.

• 4 x Bluelab peristaltic pumps for dosing A, B, Acid/Lye and additive

• 4 x 20 litre drums for A, B, Acid/lye and additive component

• Connection 220Volt 16 A 4Ph + Earth.

• Outside dimensions: 120 x 80 x 160 cm.

• 1 x bluelab controller for 1 recipe (EC + PH control)

• 1 x setting for 1 time table

• 1 x PLC for control

• Stainless steel frame + tank

Depending on the desired capacity of the water pump, you can choose from 3 types:

• 1.5 m³/h flow capacity

• 4.5 m³/h flow capacity

• 12.0 m³/h flow capacity

MI FLOW OPTIONS

Option 1: Oxygen supply

Oxygen is an undeniable element that plants need to absorb nutrition.The IPS oxygen dispenser provides a excellent and natural way of making dissolved oxygen (DO).

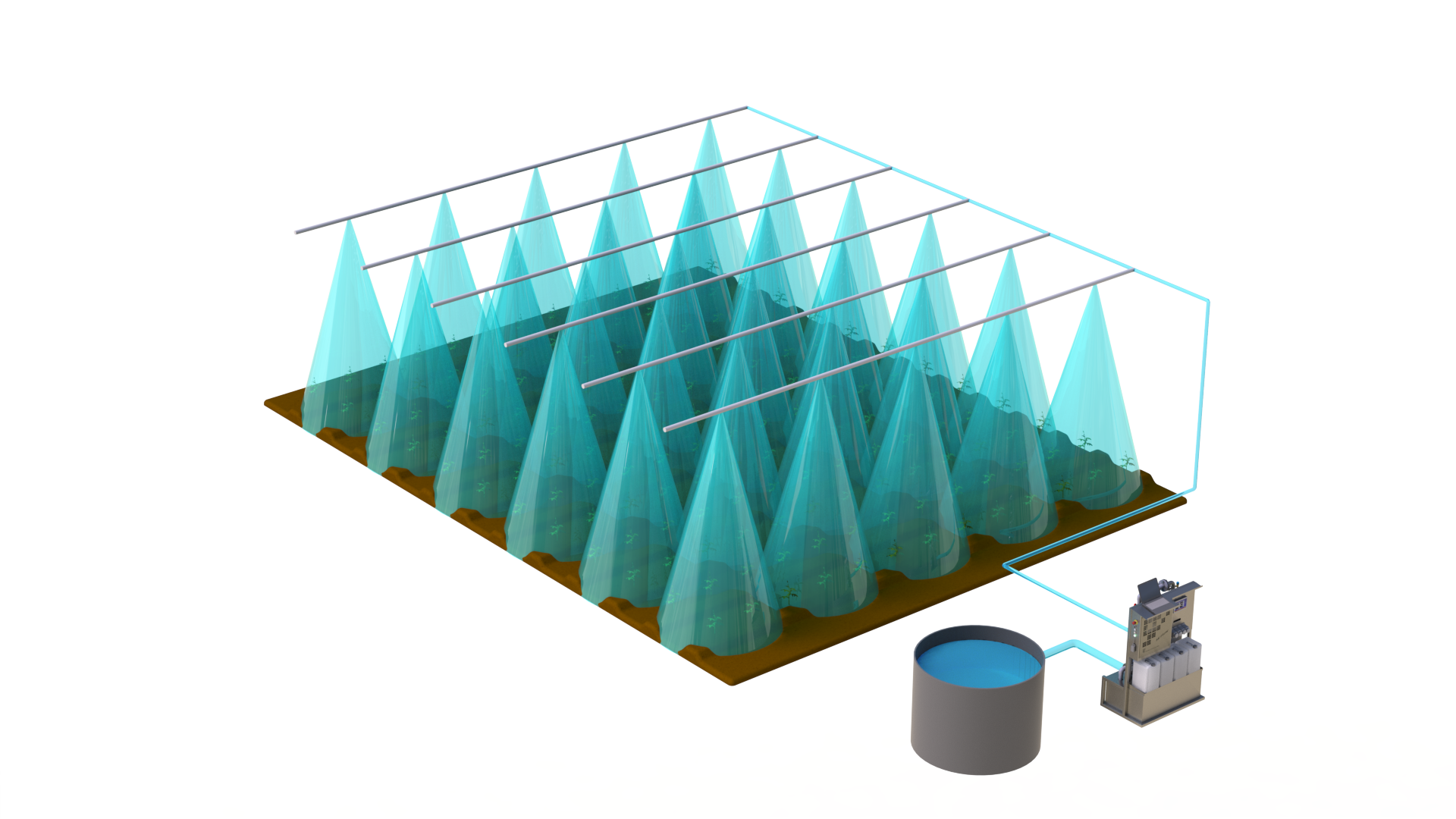

Option 2: Outgoing electrical valves

Mi flow can be expanded with valves with which you can water different sections of the greenhouse separately. With this extension, the software is also extended and you can set this choice yourself in terms of section and time. The valves are controlled by the Mi flow and supplied with power.

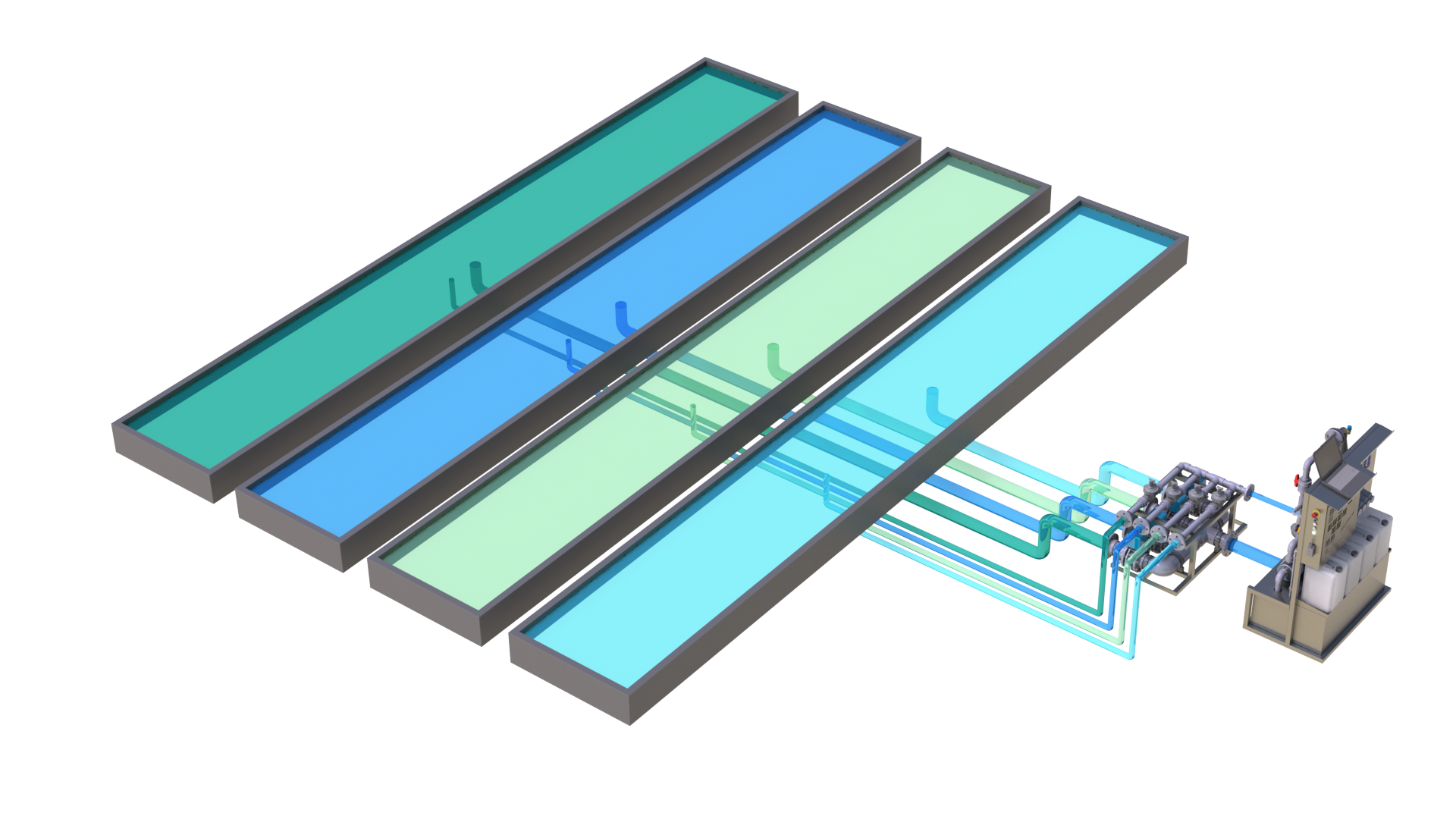

Option 3: Incoming electrical valves

For DFT systems, the water is pumped around from the pond to the Mi Flow. The pumping of water is done periodically taking into account as much rest as possible around the plants. Because the pumping takes place periodically and at a certain time, there is the possibility to use several sections in a row. With this option, the software also comes with the possibility to choose the incoming and outgoing valves in the desired time slot. Here too, the valves are controlled by Mi flow and supplied with power.

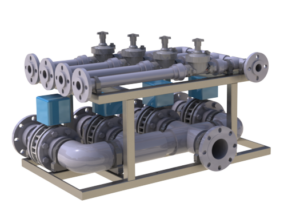

Option 4: Mi Split

The Mi Split is a stainless steel frame on which the incoming and outgoing valves are mounted and can be screwed directly to the Mi-Flow via a flange connection. The incoming and outgoing valves are equipped with a flange connection with which you can easily connect your own piping. All valves are connected to the Mi-flow by a central cable and adjusted by the software

Option 5: Remote control

In order to realize remote control on the Mi flow, a computer is placed on the water unit. The computer has an Internet connection. With this computer you have access to the following control functionalities:

• Remote access to the plc control screen. This allows adjustments to be made in the control screens of the Mi Flow unit. You can also view the alarm messages.

• Remote access in the BLUELAB controller where all settings can be adjusted and historical overviews can be created.

The computer is installed and delivered plug & play.

APPLICATIONS OF THE MI FLOW